Choose From Over 100 Types Of Hops 140 Types Of Grains And 230 Beer Recipe Kits. Plate chillers are portable and take up less room than other chiller variants.

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

Another piping consideration is the use of a one-pass waterbox.

. The dramatic reduction in chiller power oc-curs because the upstream chiller in the seriesseries counterflow arrangement operates at a higher chilled water. One of the many system modifications that has the ability to improve efficiency greatly is the use of a chiller piping strategy called Series Counter-Flow SCF. System Power for VPF with Series Chillers.

4 Application Guide AG 31-003-4 The chilled water loop flows through the evaporator of the chiller. Use of a chiller piping strategy called Series Counter-Flow SCF. This document evaluates the impact of SCF on efficiency while keeping in mind what it requires on the building controls side as well as plant design piping arrangement.

Series-Series Counterflow for Central Chilled Water Plants articleSchwedler2002SeriesSeriesCF titleSeries-Series Counterflow for Central Chilled. This document will evaluate the impact of SCF on efficiency while keeping in mind what it requires on the building controls side as well as plant design piping arrangement. The heat reclaim chiller s low source protection feature will ensure that chilled water is provided at a tem.

Reduced cooling time minimizes the presence of tannin and inhibits the formation of DMS. Design in Series. Slow it down set it back temperature etc Reduce waste.

However the condenser pump is sized for the entire system flow in this case 2400 US gpm and this pump must operate whenever any chiller operates. Chillers are piped in series counterflow if one surges it is likely that the adjacent centrifugal chiller will surge as well. Figure 6 below illustrates this domino effect of surging that is characteristic of centrifugal chillers.

However the condenser pump is sized for the entire system flow in this case 2400 US GPM and this pump must operate whenever any chiller operates. 4 Chiller System Design and Control SYS-APM001-EN Primary System Components Some chiller controls can accommodate very little flow variation during machine operation2 Other more sophisticated chiller controls allow some flow variation. Series Counterflow Chiller Design.

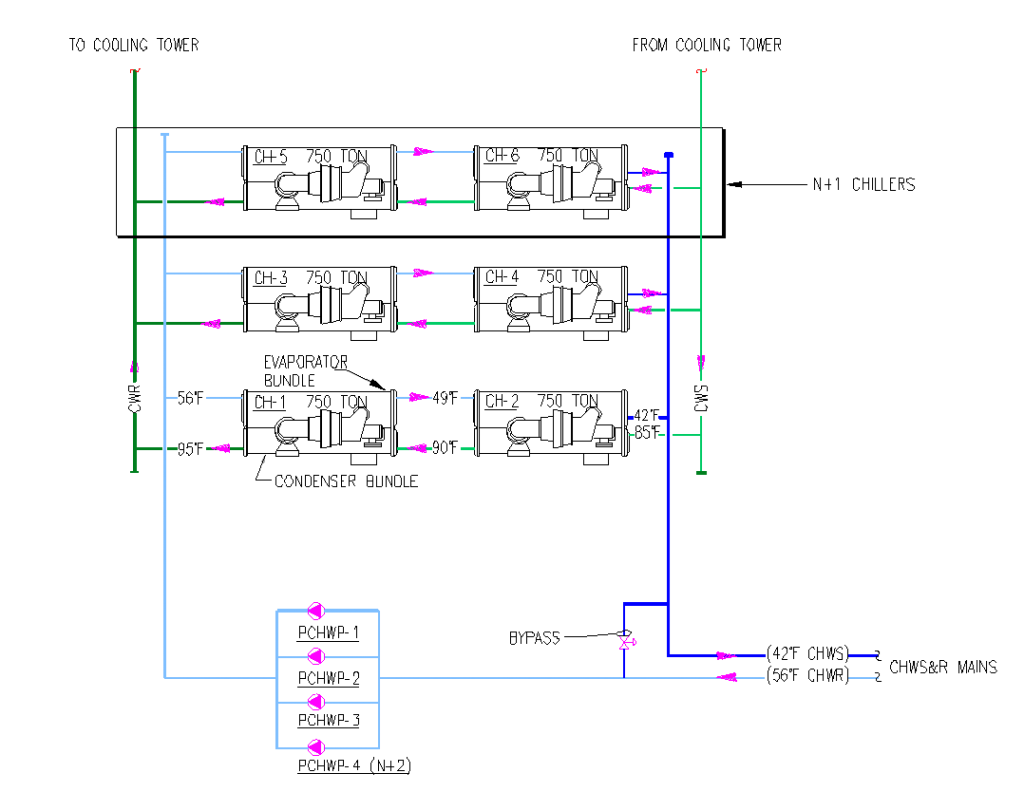

Series counterflow chillers can be 5 to 7 more efficient than a single chiller at design conditions and save up to 20 of chiller energy annually. A faster chilling process which achieves optimal cool in the short period. Basic Series Counter Flow Diagram Series Counter flow Upstream chiller CH-2 cools 60F 52F Downstream chiller CH-1 cools 52F 44F Evaporator water flows thru CH-2 and then CH-1 Condenser water flows thru CH-1 and then CH-2 90F 60F 44F 85F 52F 95F CH-1 CH-2 24 2 x 525 Ton Variable Primary.

If additional cooling is needed to maintain temp the series counter-flow chiller plant would be energized. Configuring water-cooled chiller plants in a series counterflow SCF arrangement splits the lift between two machines to enhance the operating efficiency of the plant. Some chille rs can tolerate flow-rate variationsas much as 50.

The chillers could be positioned next to each other staggered or in-line with one another sharing a common tube pull figure 3. In case one if the upstream chiller surges as a result of a rapid increase in ECdWT from 85F to 88F. In systems with constant flow through the chillers evaporators designers often specify maximum acceptable pressure drops.

The total lift produced by the series counterflow system can be up to 20 lower than a. Now one machine will cool the water from 56 to 49 F and the second machine cools it from 49. That is not less than the cooling set point.

Last week we revealed the five priorities of saving energy. A two chiller series counterflow arrangement provides an associated reduction in effective compressor lift. By Jeff Ihnen May 22 2017.

A popular system is to place the evaporators in series with the chilled water flowing from one evaporator to the next as shown in Figure 2. Chillers are piped in series counterflow if one surges it is likely that the adjacent centrifugal chiller will surge as well. It is clear from Table 1 that the series series counterflow arrangement yields the lowest full-load chiller power about 14 lower than the parallelparallel configuration.

Maximizing Infrastructure Minimizing Inefficiencies In series-series arrangements both the evaporator and condenser circuits are in series and in countercurrent flow so that the downstream chiller producing the coldest chilled water temperature rejects heat to. Opting to combine a wort plate chiller setup with brewery chillers offers several advantages which include. When it comes to piping chillers in an series counterflow configuration there is no limitation to the layout of the chillers.

Offers The Largest Selection Of Brewing Supplies To Home Brewers Across The USA. Series counter flow chillers can be 5 to 7 more efficient than a single chiller at design conditions and save up to 20 of chiller energy annually. The heat reclaim chiller would continue to control the hot.

This document will be directed toward water-cooled centrifugal chillers predominately but is. In a SCF configuration the chiller making the coldest chilled water also gets the coldest condenser water. In a SCF configuration the chiller making the coldest chilled water also gets the coldest condenser water.

Series Counter Flow Chillers The design of a chiller plant can greatly impact chiller performance. Configuring water-cooled chiller plants in a series counterflow SCF arrangement splits the lift between two machines to enhance the operating efficiency of the plant. Figure 41 - Series Counterflow System Design.

The design flow pressure drop through a pair of chillers in series is likely to be much higher than what is considered acceptable in a parallel system. The evaporator is a heat exchanger where the chilled water. Given the magnitude of the project the owner elected to outsource the design construction and operation of the 10500-ton 36 900 kW chilled water plant to an energy service company.

How Do I Model Series Counterflow Chillers In Trace 700

8 Best Wort Chiller Plus 1 To Avoid 2022 Buyers Guide Freshnss Best Mixed Drinks Fun Drinks Alcohol Spring Drink

The Benefits Of A Series Counterflow Chiller Arrangement Tlc Engineering Solutions

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

Kegco Fl Scfc Counterflow Chiller 10 1 4 Amp Quot H X 6 Amp Quot W Beer Collection Plate Chiller Home Brewing Beer

Consulting Specifying Engineer Series Counterflow Chiller Arrangement Benefits

Zchiller Wort Chiller First Looks Brewing Supplies Beer Brewing Nano Brewery

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

0 comments

Post a Comment